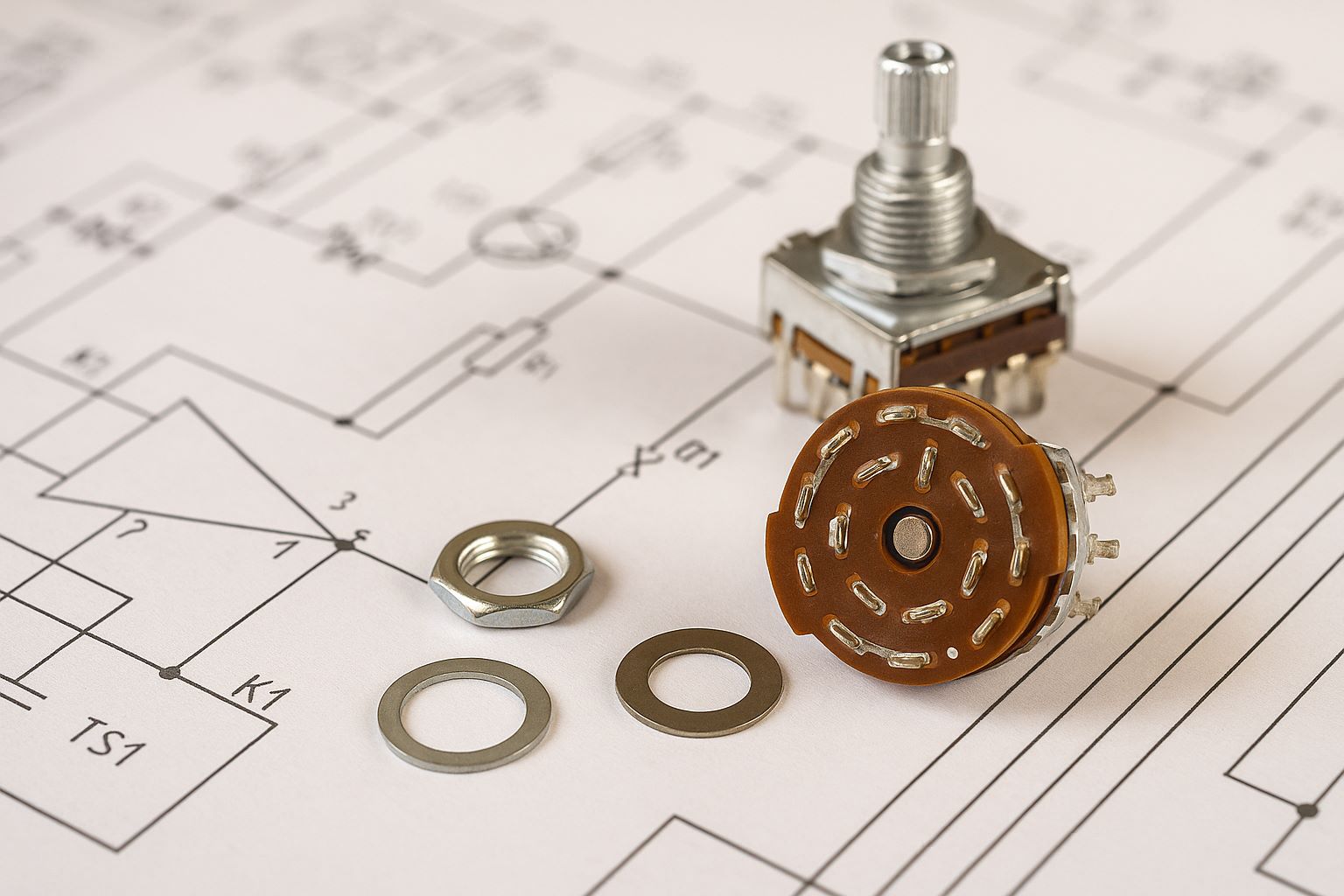

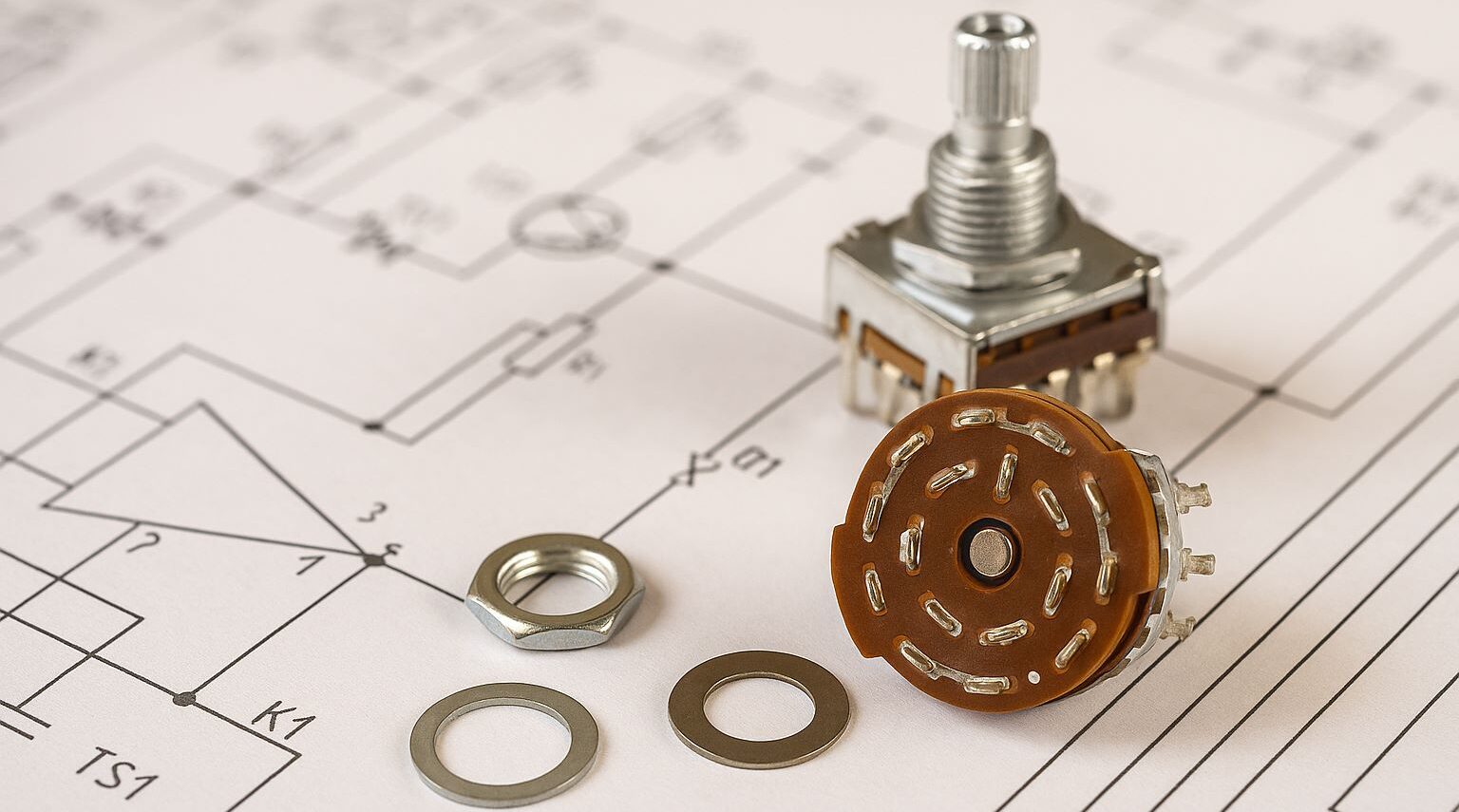

Multi-position rotary changeover switches play a vital role in many electrical systems. These switches are known for their ability to manage multiple circuits with one control point. Understanding the circuit structure behind a multi-position rotary changeover switch helps professional users select the right configuration for various technical needs.

What Is a Multi-Position Rotary Changeover Switch?

This switch allows users to control different circuits using a single rotating actuator. Each position corresponds to a different connection state. The number of switch positions typically ranges from 2 to 12, depending on system requirements.

Internal Structure: Segments and Contact Points

Internally, the switch consists of fixed contact segments and a rotating contact arm. As the actuator turns, it bridges specific fixed contacts. The contact paths change depending on the position.

For example, in a 2-position switch, the rotation toggles between two circuits. In contrast, a 12-position switch offers finer control across multiple outputs.

Additionally, most switches include detents. These mechanical steps ensure accurate alignment and prevent drift between positions.

Working Mode from 2 to 12 Positions

2–3 positions: Commonly used in simple ON-OFF-ON functions or dual-path selection.

4–6 positions: Often found in industrial control panels, providing more flexibility.

7–9 positions: Suitable for systems requiring multiple voltage or signal paths.

10–12 positions: Used in complex applications such as signal routing, test instruments, or mode selectors.

The function at each position is defined by the internal wiring. Thus, correct selection and installation are critical.

Switching Logic and Terminal Arrangement

The switching logic is usually single-pole or multi-pole. For a single-pole switch, only one circuit is changed per position. Multi-pole designs allow multiple circuits to be switched simultaneously.

Terminal arrangement also varies. Most industrial-grade switches use a radial terminal layout for clarity and stability.

It is important to note that multi-position rotary changeover switches must be wired precisely. Mistakes in wiring can lead to signal errors or circuit failure.

Common Applications and Industry Use

These rotary switches are used in several industries, including:

- Industrial automation systems

- Control panels and testing equipment

- Audio and broadcasting equipment

- Smart modules and programmable devices

For example, a 12-position switch in a signal testing bench allows users to select between multiple test points without reconnecting wires.

Advantages of Rotary Switch Design

Compared with push-button or slide switches, rotary switches offer:

Clear mechanical feedback

Compact layout for multi-functionality

Long-term durability

Easy integration into PCBs or enclosures

Additionally, their customizable circuit structure enables precise control over voltage, resistance, or signal routing.

Conclusion

Understanding the circuit structure of a multi-position rotary changeover switch is essential for correct system integration. From 2 to 12 positions, these switches support various applications with flexible, reliable switching modes.

At Fanrui, we provide high-quality rotary switches tailored to your technical requirements. Contact us to learn more about professional-grade components for your smart modules.