Why Reliable Feedback Is Crucial

In the fast-paced automotive sector, efficiency and accuracy define success. As automation grows, reliable feedback systems become essential. Sensors and encoders ensure precise control across every assembly step. Any feedback error can disrupt production, reduce quality, or lead to downtime. That’s where magnetoelectric encoders play a critical role.

These devices offer robust, real-time feedback. They survive harsh environments and deliver consistent performance. This article explores how magnetoelectric encoders drive success in automotive assembly lines.

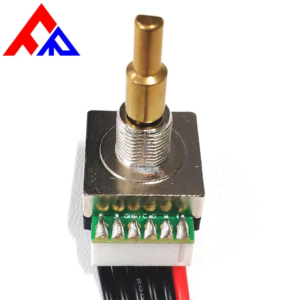

Understanding Magnetoelectric Encoders

Magnetoelectric encoders use magnetic fields to convert mechanical motion into digital signals. Unlike optical encoders, they resist dust, oil, and vibration. This makes them ideal for industrial settings.

How They Work

Inside a magnetoelectric encoder, a rotating magnet moves past a sensor. The sensor detects changes in the magnetic field. These changes convert into electrical signals. A controller interprets the signals as motion data.

This feedback helps machines monitor speed, position, and rotation. As a result, processes like welding, stamping, and painting remain precise.

Types of Magnetoelectric Encoders

Magnetoelectric encoders fall into two main types:

-

Incremental encoders: Provide relative motion data.

-

Absolute encoders: Provide exact position information at all times.

Each serves different needs within automotive assembly lines.

Challenges in Automotive Assembly Lines

Automotive production involves complex, synchronized systems. Components must move smoothly from one station to the next. The environment is full of noise, temperature changes, and mechanical stress.

Without strong feedback systems, machines lose accuracy. This results in:

-

Assembly errors

-

Increased waste

-

Machine wear

-

Higher maintenance costs

Why Conventional Feedback Fails

Traditional optical encoders struggle in these environments. Dirt and oil block sensors. Vibrations cause misalignment. Over time, accuracy drops. Production halts or quality declines.

The Advantages of Magnetoelectric Encoders

Magnetoelectric encoders overcome many of these issues. Let’s look at what makes them ideal for automotive encoders in demanding environments.

1. High Resistance to Harsh Conditions

These encoders work under extreme conditions. Dust, oil, and debris do not affect performance. Strong magnetic sensing ensures signal stability even in noisy environments.

2. Long-Term Reliability

Durability is a core strength. Many units last over 10 million cycles. This reduces downtime and saves on replacement costs. Assembly lines remain productive longer.

3. Compact and Lightweight Design

Magnetoelectric encoders fit easily into tight spaces. Compact size is essential in crowded machine setups. Low weight helps in robotic and automated arms.

4. Real-Time Data Feedback

Quick signal response allows immediate machine adjustments. This enhances the accuracy of welding, cutting, and fitting tasks. Quality improves and waste drops.

5. Simplified Installation and Integration

Many models support plug-and-play. This shortens deployment time and lowers labor costs. They integrate easily with existing control systems and PLCs.

Use Cases in Automotive Assembly

1. Robotic Arm Positioning

Robotic arms need real-time feedback to move precisely. Magnetoelectric encoders provide constant position data. Arms weld or place parts without error.

2. Conveyor Belt Monitoring

Belts must move at fixed speeds and stops. Encoders detect belt speed and position. When variations occur, the system adjusts immediately.

3. Motor Control in Torque Applications

Motors that apply torque need exact feedback. Magnetoelectric encoders help control rotation. This prevents over-tightening or loose assemblies.

4. Suspension and Chassis Assembly

In these areas, tolerances are tight. Precise movement ensures parts align perfectly. Feedback accuracy reduces costly rework.

Comparing Magnetoelectric Encoders to Other Solutions

| Feature | Magnetoelectric Encoder | Optical Encoder | Inductive Encoder |

|---|---|---|---|

| Durability | Excellent | Moderate | Good |

| Resistance to Contaminants | High | Low | Moderate |

| Size | Compact | Larger | Compact |

| Speed Feedback | High | High | Medium |

| Cost | Moderate | High | Low |

Magnetoelectric encoders offer a solid balance of cost, durability, and accuracy. That makes them ideal for modern assembly line automation.

Addressing Common Pain Points

Maintenance Downtime

Magnetoelectric encoders reduce breakdowns. Their sealed designs resist wear and damage. You spend less time fixing and more time producing.

Sensor Failure

Magnetic detection is more stable than optical sensing. Even under vibration or misalignment, signals remain accurate.

Integration Complexity

Modern encoder models come with industry-standard communication interfaces. This simplifies connection to existing PLCs or control units.

Inventory and Sourcing

With growing demand, global suppliers like Fanrui offer wholesale magnetoelectric encoder solutions. Bulk orders keep costs low and stocks available.

Industry Trends Driving Encoder Adoption

The automotive industry is moving toward full automation. With more robots, conveyors, and intelligent tools, reliable feedback is key.

1. Smart Manufacturing

Industry 4.0 demands data from every machine. Encoders supply critical motion data. This data feeds predictive maintenance systems.

2. Electric Vehicle Growth

EV production needs high precision. Battery mounting, motor assembly, and sensor placement all need reliable position control.

3. Cost-Driven Optimization

As competition increases, factories must do more with less. Efficient feedback systems reduce errors and lower overall cost.

Choosing the Right Encoder for Your Needs

Choosing the Right Encoder for Your Needs

When selecting automotive encoders, consider these factors:

-

Accuracy: Choose absolute encoders for high-precision needs.

-

Speed range: Ensure the encoder handles your motor’s max RPM.

-

Environment: Pick sealed models for harsh or outdoor setups.

-

Output signal: Match your system’s voltage and format.

-

Mounting options: Look for flange or hollow shaft models as needed.

Partnering with a supplier like Fanrui ensures technical support and product variety.

Case Study: Enhancing Assembly with Magnetoelectric Encoders

A major auto plant faced accuracy issues with its welding robots. Optical encoders failed frequently. Production stopped often for repairs.

After switching to magnetoelectric encoders, the plant saw immediate improvements:

-

Downtime reduced by 35%

-

Scrap material dropped 22%

-

Overall productivity improved by 18%

The switch paid for itself within six months. Feedback remained stable even after a year.

Conclusion

Magnetoelectric encoders are changing how automotive assembly lines work. They bring durable, precise, and real-time feedback to harsh industrial environments. Compared to traditional solutions, they offer better performance, easier integration, and long-term savings.

If you’re upgrading your production line, investing in automotive encoders is not just smart—it’s essential. With trusted suppliers like Fanrui, your automation system becomes faster, safer, and more reliable.