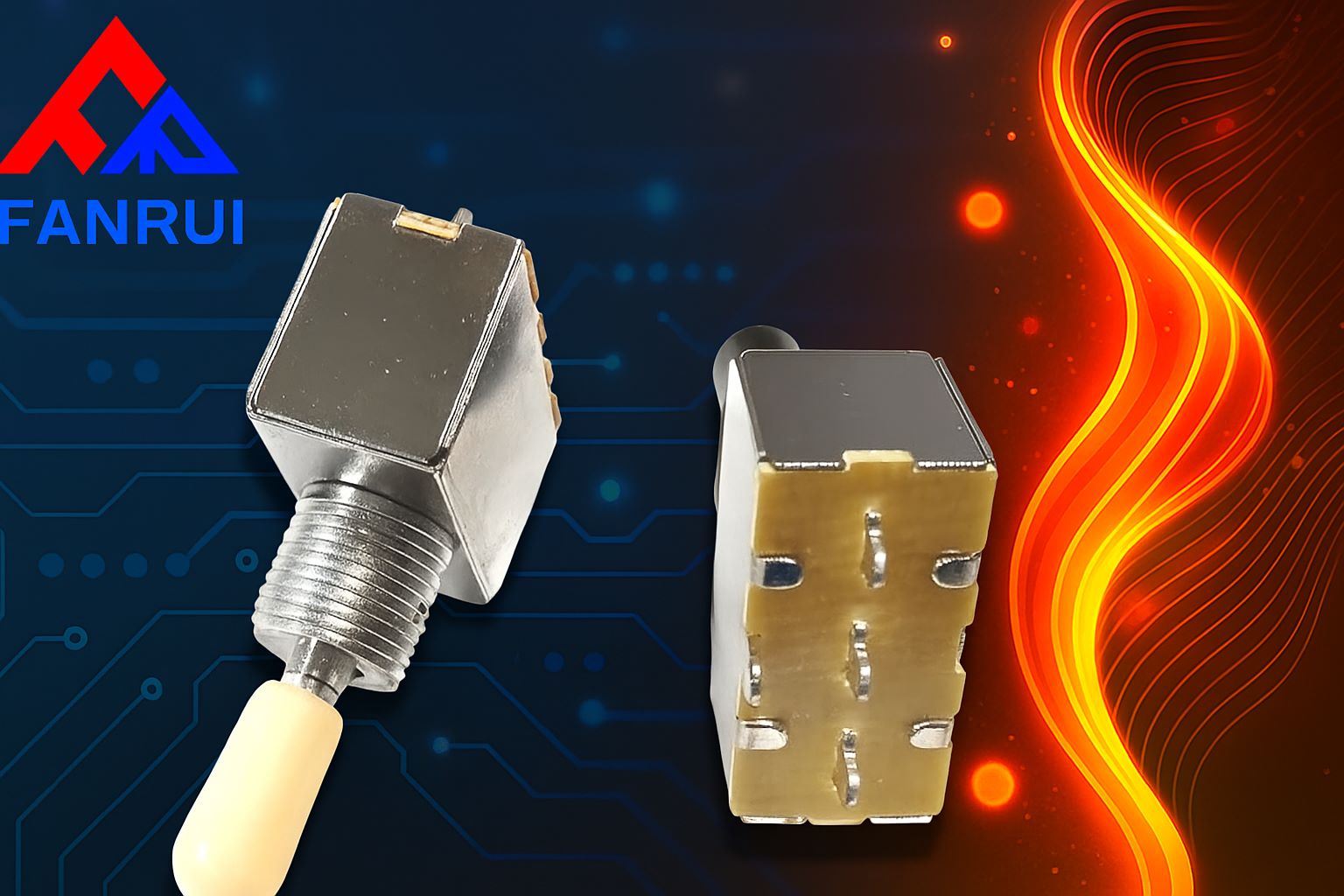

Three-gear rocker switches are widely used in modern electronics due to their simple design, intuitive control, and versatility across multiple applications. However, as devices evolve toward higher efficiency and precision, the electrical performance of these switches faces greater demands. Among the critical parameters affecting switch performance, contact resistance plays a decisive role. Elevated contact resistance not only limits current flow but also leads to heat generation, reduced durability, and inconsistent signal transmission.

Lowering contact resistance has become essential for improving conductivity, extending switch lifespan, and enhancing end-user experiences. This article explores advanced strategies, materials, and manufacturing technologies designed to minimize resistance and improve performance while considering industry regulations and user expectations.

The Role of Contact Resistance in Three-Gear Rocker Switches

Contact resistance refers to the resistance generated at the interface where conductive surfaces within a switch meet. In three-gear rocker switches, this occurs when the actuator transitions between positions, making or breaking circuits.

Even small amounts of resistance can have a profound impact on modern devices. For low-voltage systems, a minimal increase in resistance can cause significant voltage drops, leading to reduced system efficiency. For high-power applications, excessive resistance contributes to heat buildup, which accelerates wear and potentially damages components.

Therefore, the optimization of contact resistance directly translates into improved conductivity, energy efficiency, and thermal stability.

Factors Influencing Contact Resistance

Several key factors affect the contact resistance in three-gear rocker switches:

-

Material Properties

Conductive materials like copper, silver, and gold offer different resistivity levels. Surface oxidation or impurities can significantly increase resistance. -

Surface Roughness

Microscopic imperfections on the contact surface reduce the effective area of conduction. A smoother surface ensures greater contact uniformity and lower resistance. -

Contact Force

Adequate pressure between contact points ensures a stable conduction path. However, excessive force can deform components, while insufficient force leads to intermittent performance. -

Environmental Factors

Humidity, dust, and exposure to corrosive gases accelerate surface degradation and increase resistance over time. -

Mechanical Wear

Frequent actuation of the rocker switch wears down the plating and alters its conductive properties, requiring robust material solutions.

Advanced Strategies to Reduce Contact Resistance

1. Optimizing Conductive Materials

Using high-conductivity metals like silver or gold-plated copper significantly improves performance. Gold offers superior resistance to oxidation, making it ideal for precision applications. Meanwhile, silver provides excellent conductivity at a lower cost, though it requires surface treatments to minimize tarnish.

Fanrui integrates advanced plating technologies into its three-gear rocker switches, ensuring low-resistance surfaces even after prolonged use.

2. Enhancing Surface Treatments

Modern switch manufacturing leverages surface treatments like:

-

Electroplating: Depositing thin conductive layers ensures smooth, uniform contacts.

-

Anti-oxidation coatings: Protective layers reduce environmental degradation.

-

Nano-coatings: Advanced thin films improve conductivity while resisting corrosion.

By combining these methods, manufacturers achieve stable, long-term performance in high-humidity or high-dust environments.

3. Precision Engineering for Contact Force

Maintaining optimal contact pressure is essential for minimizing resistance. Fanrui employs CNC-controlled forming and precision spring design to ensure consistent force across all switching cycles. Controlled tolerances guarantee a reliable conduction path while preventing mechanical deformation over time.

4. Reducing Heat Buildup

Since higher resistance generates heat, thermal optimization plays a crucial role. Fanrui uses thermally stable materials and advanced heat dissipation structures to mitigate temperature rises in high-current applications. This not only enhances conductivity but also prolongs product lifespan.

5. Environmental Sealing and Dust Protection

To counter environmental factors, Fanrui’s three-gear rocker switches incorporate IP-rated enclosures and sealed contact chambers. These features protect the conductive surfaces from moisture, dust, and chemical vapors, preventing corrosion and maintaining consistent low resistance even under harsh operating conditions.

The Role of Manufacturing Technologies

Reducing contact resistance requires more than material improvements. Advanced manufacturing technologies, such as:

-

Laser surface micro-polishing to minimize roughness.

-

High-precision injection molding for consistent component alignment.

-

Automated inspection systems to ensure plating integrity and defect-free assembly.

By integrating these processes, Fanrui ensures every rocker switch meets stringent global standards for electrical performance.

Applications Driving the Demand for High Conductivity

The need for lower contact resistance extends beyond performance optimization; it also reflects the demands of evolving applications:

-

Consumer electronics: Devices require efficient, low-loss switching to maintain battery life.

-

Automotive systems: High-current circuits demand minimal heat generation and reliable conduction.

-

Industrial controls: Complex automation setups need precise, durable switches.

-

Smart home technologies: Compact, energy-efficient designs rely on optimized conductivity.

Future Development Trends

With the growing adoption of smart electronics and high-efficiency systems, reducing contact resistance will remain a focal point of innovation. Emerging trends include:

-

Integration of graphene-based coatings for ultra-low resistivity.

-

AI-driven predictive wear analysis for extended component life.

-

Hybrid material designs combining mechanical durability with advanced conductivity.

Conclusion

Reducing contact resistance in three-gear rocker switches is no longer just an engineering preference; it is an industry necessity. By optimizing conductive materials, refining surface treatments, and integrating precision manufacturing, companies can achieve higher efficiency, better heat management, and longer-lasting performance.

Fanrui is committed to delivering high-quality electronic switch components that meet these rigorous demands. Through continuous innovation and adherence to international standards, Fanrui empowers clients to design products that thrive in competitive global markets.

For brands seeking reliable, high-conductivity three-gear rocker switches, Fanrui provides both expertise and advanced solutions to meet the evolving challenges of modern electronics.