In the evolution of human-machine interfaces (HMI), a persistent tension exists between the physical and the digital. On one hand, professionals in audio engineering, industrial control, and medical imaging crave the “analog feel”—the weighted resistance and immediate tactile feedback of a physical slider or knob. On the other hand, the modern Internet of Things (IoT) ecosystem demands data-driven precision, scene presets, and the ability to control parameters from across the globe.

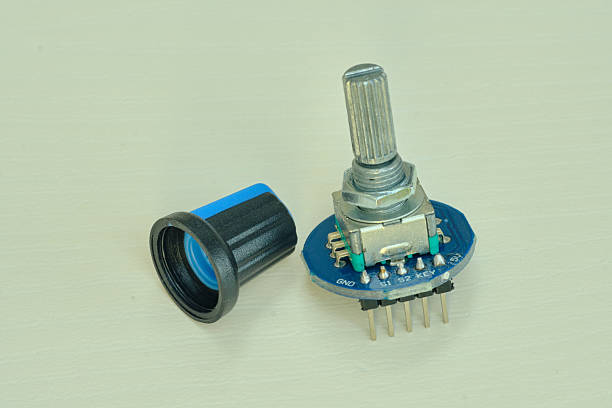

The solution to this conflict is the digital output potentiometers—a specialized hybrid component that integrates high-resolution absolute encoders with traditional resistive structures. By merging a high-precision Analog-to-Digital Converter (ADC) with the classic mechanical “fader” feel, these components allow for the “Analog Touch” while enabling the “Digital Mind.” This article explores how smart potentiometers act as the bridge between classic interaction and intelligent systems, redefining how we manage parameters in a connected world.

1. The Tactile Imperative: Why the “Analog Feel” Still Matters

Despite the ubiquity of touchscreens, the physical potentiometer remains irreplaceable in high-stakes environments.

The Psychology of Friction

When an audio engineer slides a fader or a surgeon turns a dial, they rely on “muscle memory.” The physical resistance (torque) of the potentiometer provides a sensory feedback loop that a flat screen cannot replicate. This tactile connection allows for “blind operation,” where the user can adjust parameters based on feel while keeping their eyes on the stage or the patient.

The Resolution of Continuity

A traditional potentiometer offers infinite resolution within its travel range. To preserve this experience in the digital realm, digital output potentiometers must capture every microscopic movement without the “stepping” or “zipper noise” often associated with low-end digital encoders.

2. Decoding the Intelligence: Encoders and ADCs

2. Decoding the Intelligence: Encoders and ADCs

The “Smart” aspect of a modern potentiometer comes from the integration of secondary sensing technologies beneath the mechanical track.

Integrated Absolute Encoders

Unlike incremental encoders that lose their “place” when power is cut, absolute position encoders within the potentiometer provide a unique digital code for every specific coordinate on the track.

-

The Action: The moment the device powers on, the system knows exactly where the slider is located without requiring a “reset” to zero.

-

The Result: This enables absolute parameter mapping, which is essential for safety-critical industrial machinery.

High-Precision (ADC) Integration

Many smart potentiometers now house an onboard 12-bit or 16-bit ADC. This chip converts the analog voltage sweep into a high-speed digital bitstream (such as I2C or SPI). By performing the conversion inside the component itself, the signal becomes immune to the electromagnetic interference (EMI) that often plagues long analog cable runs in factory floors or recording studios.

3. Scene Presets: The Power of “Parameter Memory.”

One of the greatest limitations of traditional potentiometers is their inability to “remember” a state. If you change a setting, the previous position is lost forever.

One-Touch Recalls

By utilizing the digital output of a smart potentiometer, a system can save the exact position of the fader as a “Scene Preset.”

-

Scenario: In a theater lighting setup, a technician might spend hours perfecting the “Sunrise” scene. With digital output potentiometers, the system saves the 10-bit position value to the cloud.

-

The Metamorphosis: When the scene is recalled, the software highlights the target position on a screen, or—in the case of motorized versions—physically moves the fader to the saved spot. This ensures 100% repeatability across different shifts or performances.

4. Remote Control and the IoT Bridge

The integration of digital output transforms the potentiometer into an IoT “Edge” device. Once the physical movement is converted to a digital signal, it can be transmitted across any network.

Global Parameter Adjustment

A supervisor in a central command center can monitor the physical position of a potentiometer on a remote oil rig. If a parameter exceeds safe limits, the digital twin of that potentiometer reflects the change instantly.

-

Bi-Directional Communication: In advanced setups, the remote operator can send a command back to the device. If the potentiometer is a motorized digital hybrid, the physical knob will turn itself to match the remote instruction, providing a visual warning to the local operator.

Predictive Maintenance through Data

By tracking the digital output over time, AI systems can monitor the “health” of the component. If the digital signal shows jitter or inconsistency in a specific section of the track, the system can flag the potentiometer for maintenance before a physical failure occurs.

5. Engineering the “Gold Standard” of Interaction

To successfully blend these two worlds, the mechanical design of the digital output potentiometers must meet rigorous standards.

-

Customizable Torque: Manufacturers can “tune” the internal lubricants to provide anything from a “light-and-fast” feel for DJ mixers to a “heavy-and-damped” feel for industrial cranes.

-

High Cycle Life: Because these components are often used in high-frequency environments, they frequently feature conductive plastic tracks or non-contact magnetic sensing to ensure millions of cycles without signal degradation.

-

Seamless Integration: By offering standard form factors, these smart components allow engineers to upgrade existing analog products to “Smart” status without redesigning the entire physical chassis.

6. Conclusion: The Future is Tactile and Connected

At the intersection of touch and technology, digital output potentiometers redefine progress without sacrificing intuition. By preserving the familiar analog feel, they seamlessly integrate encoders, ADCs, and IoT connectivity. As a result, each interaction satisfies both human touch and digital precision.

Meanwhile, smart factories and automated homes increasingly demand these haptic bridges. They enable remote control, scene recall, and tactile feedback in one interface. Ultimately, at Fanrui-level precision, every turn becomes a dialogue with the future.