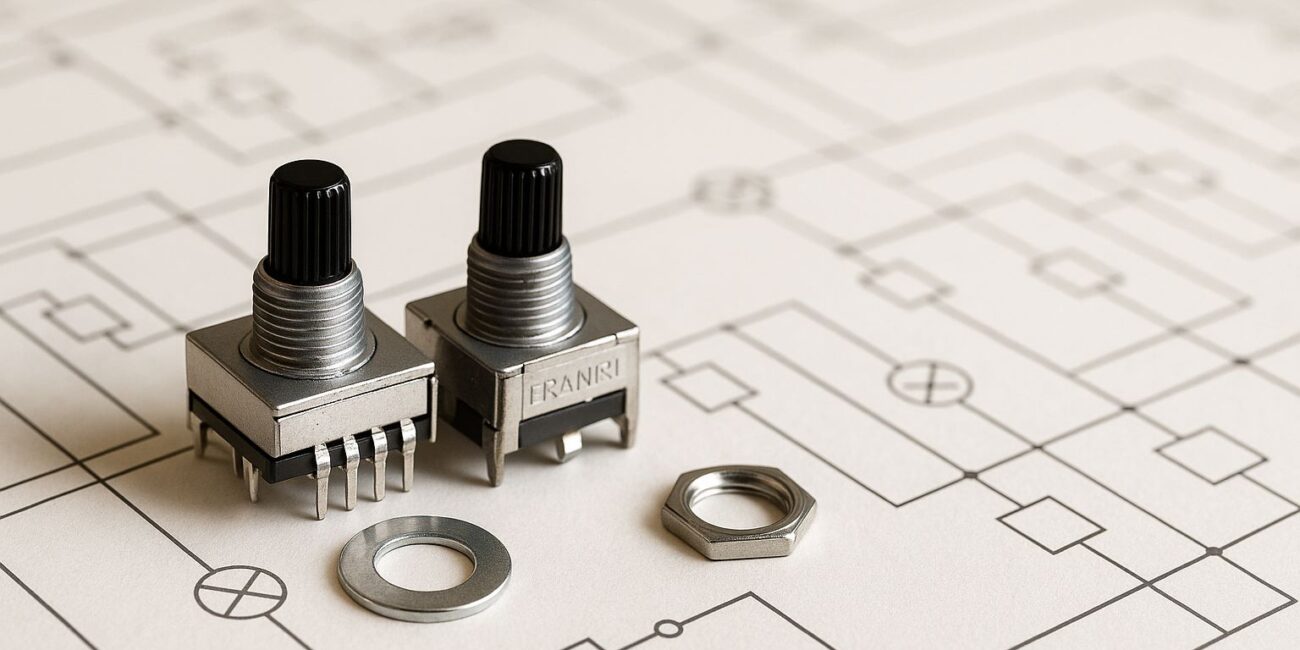

Users expect flawless performance from their audio equipment. A single scratchy sound from a volume knob can ruin the experience. This common frustration often originates from a single, critical factor within the volume potentiometer: contact pressure. As a leading specialist in component design and manufacturing, Fanrui understands this fundamental relationship deeply. We engineer our potentiometers to master contact pressure. This mastery delivers exceptional, noise-free performance and long-term reliability for your products.

Understanding the Core: The Wiper and Trace Interface

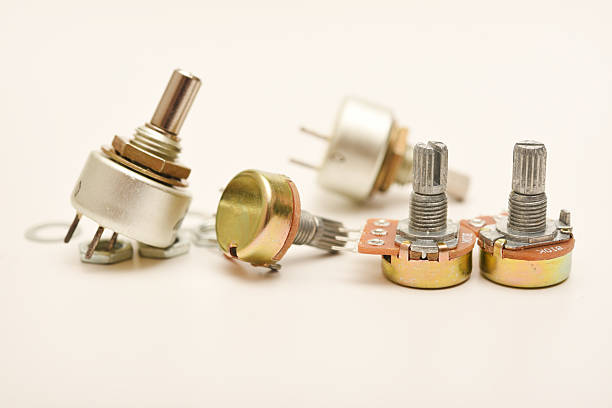

First, consider the basic function of a rotary volume potentiometer. It controls the signal level by varying the resistance. A conductive wiper moves along a resistive track or trace. This movement changes the output. The electrical connection at this wiper-to-trace interface is absolutely vital. It is not a simple mechanical touch. It is a dynamic electrical junction governed by physical principles.

Contact pressure defines this interaction. It refers to the consistent, controlled force the wiper exerts on the resistive track. This pressure must remain optimal throughout the potentiometer’s rotational life. Engineers must balance several competing demands. Too little pressure causes intermittent contact. Too much pressure accelerates wear. Both extremes lead directly to operational failure and user dissatisfaction.

The Direct Link: Pressure, Noise, and Crackle

Now, let’s examine the precise mechanisms linking pressure to audible defects.

Insufficient Contact Pressure creates a precarious connection. The wiper may bounce or float microscopically over the track surface during adjustment. This action causes intermittent signal breaks. These breaks manifest as static crackle or popping sounds in the audio path. Furthermore, low pressure increases electrical contact resistance at the interface. This elevated resistance becomes a source of consistent background noise or hiss. Environmental factors like vibration exacerbate these issues significantly. Dust ingress also finds an easier path to disrupt the already weak connection.

Excessive Contact Pressure presents a different set of problems. It causes abnormally high mechanical friction. This friction leads to accelerated abrasive wear of both the wiper contact point and the delicate resistive track. As wear particles accumulate, they create a gritty, scratchy noise during rotation. More critically, the worn track develops an uneven surface or microscopic pits. This damage creates non-linear resistance changes. The result is channel imbalance or tracking errors. Ultimately, the potentiometer fails prematurely. Its rotational life falls far short of its specified cycle count.

Therefore, achieving and maintaining the Goldilocks Zone of contact pressure is not just ideal. It is essential for premium audio performance.

Fanrui’s Engineering Solutions for Optimal Contact Pressure

At Fanrui, we treat contact pressure as a system-wide design parameter. We do not leave it to chance. Our engineering approach integrates material science, precision mechanics, and rigorous validation. This integration ensures every volume potentiometers deliver consistent, silent operation.

1. Precision Wiper Design and Material Selection:

We design our wipers with meticulous attention to geometry and spring characteristics. The wiper’s form dictates the pressure distribution profile across the track. We use advanced alloys and composite materials for the spring element. These materials provide a stable, predictable force over millions of cycles. They resist fatigue and stress relaxation. Our selection of precious metal plating for the contact point (e.g., gold, silver-palladium) ensures low and stable contact resistance. This selection minimizes the inherent noise figure from the outset.

2. Advanced Resistive Track Technology:

The track is not a passive component. Its composition and topography directly interact with the wiper. We utilize high-uniformity conductive polymers or precision cermet (ceramic-metal) tracks. These materials offer excellent surface smoothness and wear resistance. A smoother track requires less aggressive wiper pressure for a stable electrical connection. This synergy reduces mechanical wear and inherent noise generation. Our manufacturing processes guarantee exceptional concentricity and flatness. This guarantee eliminates localized pressure spikes that cause uneven wear.

3. Robust Mechanical Structure and Assembly:

A wiper cannot maintain optimal pressure within substandard housing. We manufacture our potentiometer housings and shafts to exacting tolerances. This precision prevents bearing play or shaft wobble. Such imperfections would otherwise vary the contact pressure during rotation. Our automated assembly processes apply consistent calibration and actuation torque settings. This consistency ensures every unit leaving our production line meets the same stringent performance standard. Batch-to-batch variability becomes virtually nonexistent.

4. Comprehensive Testing and Validation:

Our commitment extends beyond design into verification. We subject our volume potentiometers to extended cycle testing under electrical load. We monitor contact resistance variation (CRV) and rotational noise continuously. Environmental stress tests, including temperature cycling and humidity exposure, validate performance stability. These tests confirm that our contact pressure management withstands real-world conditions. They prove our components resist the formation of noise and crackle over time.

The Fanrui Advantage for Your Audio Applications

Choosing Fanrui as your potentiometer supplier translates this technical expertise into tangible benefits for your brand.

-

Superior Audio Fidelity: Our volume potentiometers provide a clean, transparent signal path. They preserve the integrity of your audio design without adding noise or distortion.

-

Enhanced Product Longevity: Products equipped with our components demonstrate remarkable durability. The dreaded “scratchy volume knob” complaint disappears, boosting product reputation and reducing warranty claims.

-

Design-In Partnership: We collaborate closely with your engineering team. We help optimize the selection from our broad range of audio-grade potentiometers. We consider your specific requirements for impedance, taper, size, and termination style.

-

Supply Chain Reliability: As a direct manufacturer, we guarantee consistent quality and stable supply. You mitigate the risk of receiving subpar components that compromise your end-product’s performance.

Conclusion: Precision as the Foundation of Silent Control

In conclusion, contact pressure is the silent arbiter of performance in every volume potentiometer. It directly dictates the presence or absence of noise, crackle, and wear. Mastering this parameter requires a holistic approach to design, materials, and manufacturing control.

Fanrui dedicates its expertise to this precise mastery. We engineer our audio potentiometers to operate flawlessly at the critical wiper-track interface. This focus ensures your customers experience only pure sound and smooth, silent control. Do not let a minor component undermine a major investment in your product’s quality.

Contact Fanrui today. Let us demonstrate how our precision-engineered volume potentiometers can become the reliable, noise-free heart of your audio control solutions. Partner with us to eliminate compromise and define a new standard for acoustic clarity in your applications.